About

Hindon is a specialty supplier of highly technical engineered industrial products. Our products serve as critical components of machinery used in challenging industrial applications such as those seen in bulk material handling and process industries.

By combining robust engineering expertise, relationships with leading global manufacturers whose products we’ve spent decades learning inside and out, and our own fabrication and design capabilities, we are able to provide reliable and cost-effective solutions that help our customers minimize downtime and maximize productivity.

Working with a range of customers including OEMs, engineering firms, and end users of industrial machinery, we specialize in providing solutions that serve our customers’ specific needs. Customers value the reliability of our products and solutions, our technical knowledge and application experience, and our commitment to service/support throughout the product lifecycle.

Simply put: we are passionate about our products and supporting those who depend on them.

Hindon’s facility in Charleston, South Carolina

History

Husband and wife entrepreneurs Mike and Loretta Nickel founded Hindon in 1983 when they discovered the value they could provide the industrial marketplace by specializing in application and support of niche, highly technical, products. With a focus on challenging bulk material handling applications, Mike and Loretta Nickel began Hindon’s now long-running tradition of providing solutions that incorporate engineered industrial products that require a deep technical understanding of each product’s capabilities/limitations and how to apply these products to various applications to achieve the desired result.

In 1987, Loretta’s son, Eric Schulz, joined Hindon as the industrial vibrator salesperson and oversaw the growth of Invicta Vibrators in the U.S. He became company President in 1993 when his stepfather became unexpectedly ill.

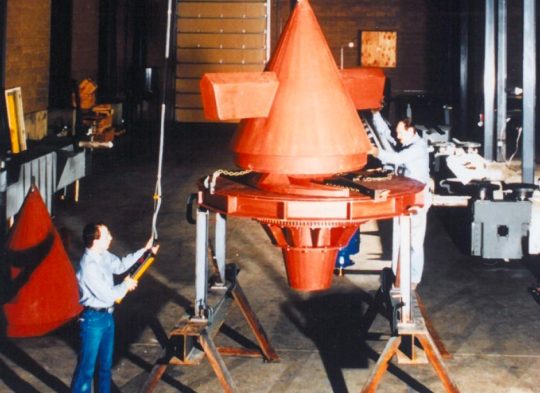

In 1995, Bradley Hunt joined Hindon and was instrumental in further developing Hindon’s robust consultative engineering approach, especially as it related to Hindon’s industrial braking systems. Brad also designed Hindon’s ROPLEX™ Rotary Discharger, a live bottom feeder with a rugged, yet maintenance friendly, design. To recognize his leadership efforts and product design achievements, Brad was made an equity owner alongside Eric Schulz.

After running Hindon for over two decades, Eric and Brad began to consider how best to transition the company to ensure its long-term success. In 2019, the owners capitalized on the opportunity to transition ownership and leadership of the company to Noah Krimm, who shared their and the family’s passion for industry, manufacturing, and entrepreneurship.

Today, Hindon maintains its over 40-year commitment to delivering the right product solutions engineered to the unique requirements of our customers’ industrial applications and supporting our products and the people who depend on them however we can.

We look forward to working with you.

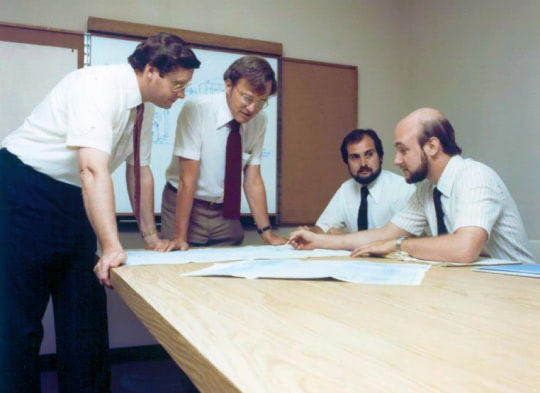

Hindon’s engineering team circa 1985

An early design of Hindon’s ROPLEX™ Discharger Assembly

Industrial vibrator inventory in 1984

Technical Capabilities

Hindon’s robust technical capabilities and institutionalized product knowledge back our commitment to comprehensive service/support for those who depend on our products.

Our technical capabilities include:

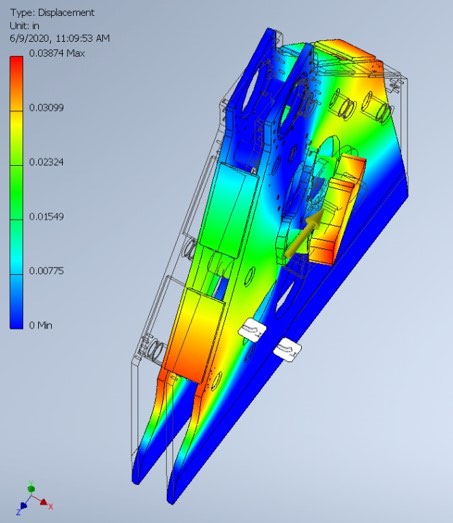

- Finite Element Analysis (FEA)

- CAD Modeling

- Design/Fabrication of Custom Components and Assemblies

- Application-Specific Formulas and Models

- Detailed Understanding of Hazardous Areas (North American and European Standards)

- Repair Services for Everything We Sell

Our engineers use FEA to help customers ensure deflection is within allowable limits