Automatic Cooling Tower Brakes

We designed the Hindon Automatic Braking System for Cooling Towers to help American infrastructure stay one step ahead of mother nature.

Our cooling tower brakes provide several benefits to coastal power plants and refineries looking to become more hurricane resilient.

Benefits

Our remote-activated automatic brakes mean an operator doesn’t have to be present to manually lock down the cooling tower fan. This provides two main benefits:

- Eliminates a dangerous task for your operators

- Allows you to keep running longer while a storm is approaching and allows you to start up faster after the storm passes

High Winds

Because Hindon’s brakes can be activated from the control room with the push of a button, you don’t have to worry about locking down the cooling tower before high winds arise.

OHSA defines high winds as “winds exceeding 64.4 kilometers per hour (40 miles per hour).” OHSA considers it a hazard to have employees working in an elevated location, such as a cooling tower, in high winds.

Increased Uptime

Leading up to and during a hurricane, the difference between 40 mph winds and the speed at which you would consider shutting off your tower to prevent other damage could be days-worth of production.

During Hurricane Dorian (2019), a leading Florida utility company that installed Hindon’s Automatic Braking System was able to provide uninterrupted production throughout the storm. Winds exceeded 40 mph for several days as Hurricane Dorian moved slowly up Florida’s eastern coast, but winds never topped the ~90 mph at which the Company would have needed to secure the fans to avoid possible damage to the fan and cooling tower. As a result, they were able to continue production throughout the storm.

Avoiding Costly Damage During Hurricanes

Being able to safely secure a cooling tower fan as winds approach hurricane strength also helps avoid costly damage to your operation. According to the U.S. Department of Energy, “securing the fan blade is considered the most important component of storm-hardening a cooling tower.” Hurricane force winds can over-speed a fan and cause a blade to detach in the tower. High winds can also cause the fan cowl to deflect or bend, resulting in catastrophic interference with the fan.

Avoiding Costly Damage Upon Startup

Lastly, our braking system can prevent damage during the motor starting sequence. Oftentimes, an un-braked fan will freewheel in the reverse direction. Starting the fan motor while the fan is freewheeling in reverse can cause serious shock loading damage to your system, including snapping the driveshaft or damaging the gear unit. Our cooling tower brakes synchronize with the PLC in the plant control system to release the brake milliseconds before starting the motor. This prevents the fan from being able to develop the reverse rotating inertia that can potentially damage the drive train during startup.

How it Works

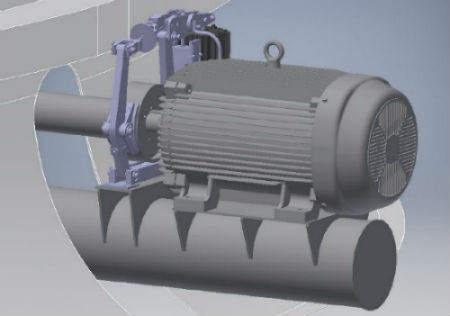

We custom design our Automatic Braking System based on the customer’s cooling tower equipment and configuration. We make sure the brakes are sized appropriately relative to the existing motor and gearbox. As we do with all of our fail-safe braking systems, we also ensure the brakes work with any existing space constraints.

Our Automatic Braking System uses a thruster drum brake. Drum brakes are ideal for this application because they are cost-effective and can serve as an effective holding brake. An electrohydraulic thruster is an ideal way to actuate these brakes because of its durability and dependability, especially in this high-duty cycle application where the brake will typically be held open.

We also typically outfit our Cooling Tower Brakes to automatically adjust for lining wear. This minimizes the maintenance requirement and enhances system reliability. We also use a passive adjustable time delay. This provides adjustable sequencing for a smooth stop that minimizes impact forces to the driveshaft in a power failure.

Because of its robust design, our Automatic Braking System for Cooling Towers can be used in any power plant, refinery, steel mill, or processing facility that uses a cooling tower.

Commitment to service and support

Hindon is dedicated to providing comprehensive support for our products and the people who depend on them. From initial consultation to inspection, maintenance, and repair services, our goal is to provide the right equipment for your application and to keep your product in top shape for its full lifecycle. If you’re not sure which product is right for your application, call or chat with one of our sales engineers.